Optimizing Picking, Packing, and Fulfillment Processes

Picking Efficiency

Picking efficiency in a warehouse setting is paramount to overall operational success. Optimizing picking procedures directly impacts order fulfillment speed and accuracy, leading to a significant boost in customer satisfaction. This involves a careful analysis of current picking methods, identifying bottlenecks, and implementing strategies to streamline the process. For instance, utilizing a well-organized picking system, such as a zone-based or batch-picking method, can drastically reduce travel time between locations within a warehouse. Employing barcode scanners or RFID technology for inventory tracking further enhances accuracy and minimizes errors.

Another key aspect of optimizing picking efficiency is employee training. Well-trained personnel are better equipped to navigate the warehouse layout, locate items quickly, and follow established procedures. Comprehensive training programs should cover proper picking techniques, safety protocols, and inventory management systems, resulting in a more productive and reliable workforce. This will not only improve the speed of picking but also reduce the likelihood of picking errors.

Packing Procedures

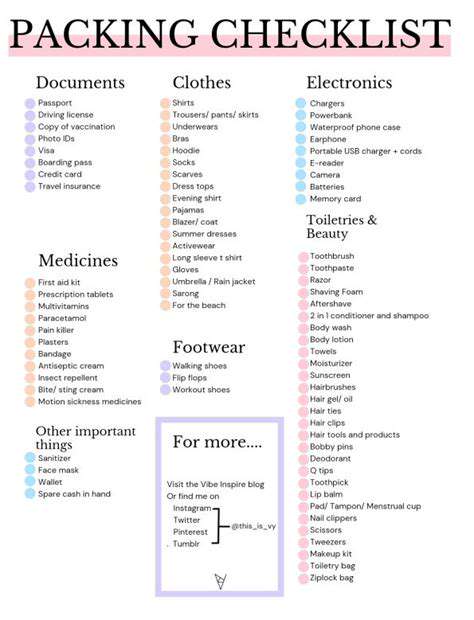

Packing procedures are crucial for preserving product quality and ensuring safe delivery. Robust packing materials and methods not only protect goods during transit but also convey professionalism and care to the customer. Appropriate packaging selection is critical, considering the product's fragility, size, and weight. Proper cushioning and protective inserts are essential to prevent damage during transport. Employing standardized packing procedures can also help streamline the process, allowing for faster and more consistent packing times.

Furthermore, effective labeling and documentation are vital components of the packing process. Clear and accurate labeling ensures that the correct items are packaged and shipped to the right destination. This also includes adherence to shipping regulations, which can vary depending on the destination and the product being shipped. Thorough labeling, including tracking information and special handling instructions, contributes to the overall efficiency and security of the packing process.

Fulfillment Strategies

Effective fulfillment strategies encompass a comprehensive approach to order processing, from initial order entry to final delivery. Efficiently managing the flow of orders through various stages of processing is key to maintaining a smooth and rapid fulfillment cycle. This includes a clear understanding of current order volumes, peak periods, and potential disruptions to the process. By leveraging technology and analytical tools, warehouses can anticipate demand fluctuations, adjust staffing levels accordingly, and optimize resource allocation.

Implementing a robust system for tracking order status and communication with customers is also crucial. This transparency builds customer trust and confidence. Real-time updates on order progress, proactively addressing potential delays, and providing clear communication regarding delivery timelines are vital to maintaining excellent customer service. This will create a more reliable and satisfactory order fulfillment process, ultimately leading to increased customer loyalty.

Inventory Management

Effective inventory management is the bedrock of a successful picking, packing, and fulfillment operation. Maintaining accurate inventory records is essential for avoiding stockouts and overstocking, impacting profitability and customer satisfaction. Implementing a sophisticated inventory management system, such as a warehouse management system (WMS), can automate tracking, forecasting, and reordering, ensuring optimal stock levels. This will minimize the risk of lost sales due to shortages and reduce unnecessary holding costs associated with excess inventory.

Regular cycle counting and physical inventory audits are critical for maintaining accuracy in inventory records. These processes help identify discrepancies between the recorded and actual inventory levels. Promptly addressing discrepancies and implementing corrective actions minimizes errors in order fulfillment and helps improve the overall warehouse operational efficiency. This, in turn, leads to a more accurate and reliable inventory system.